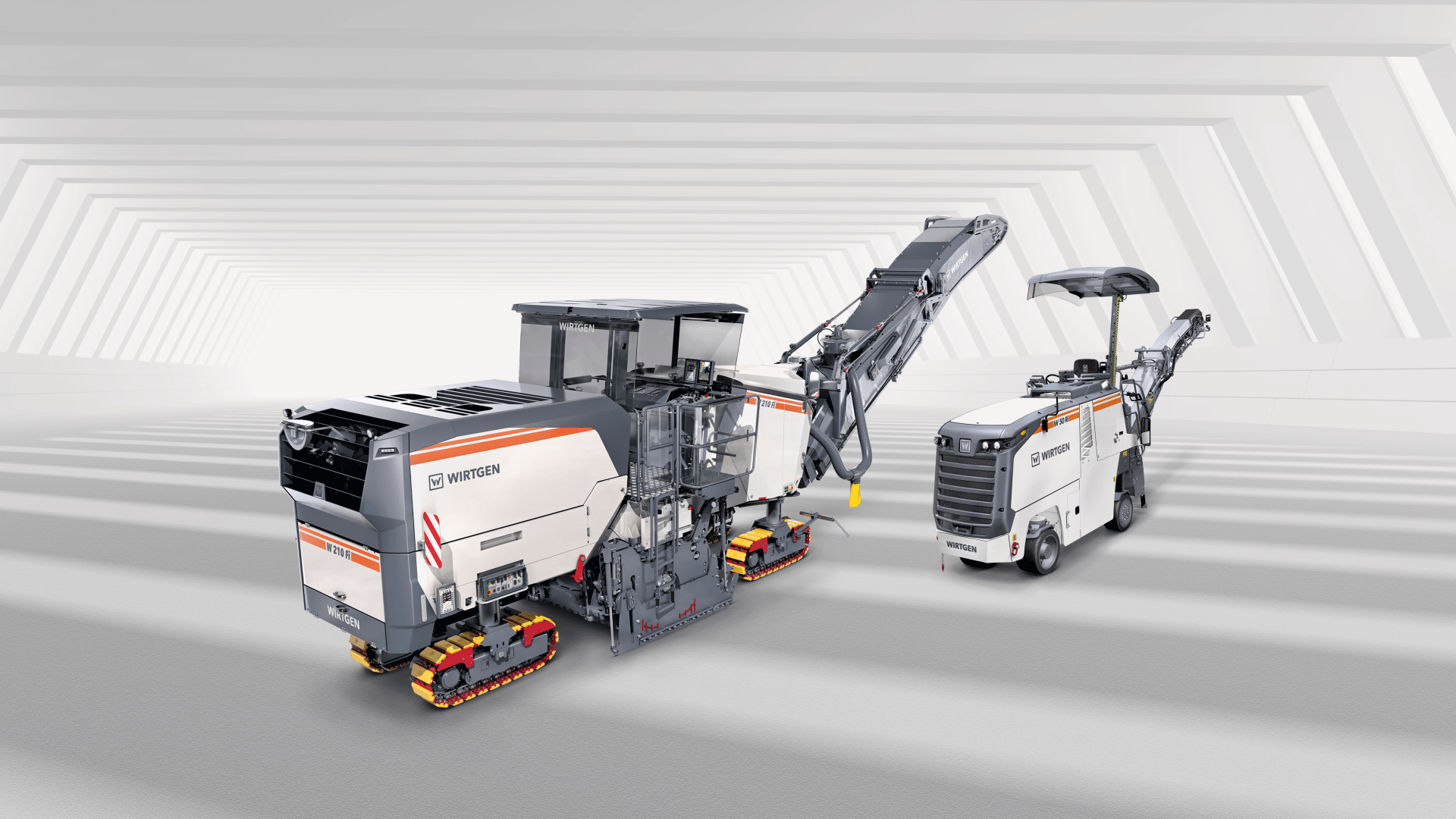

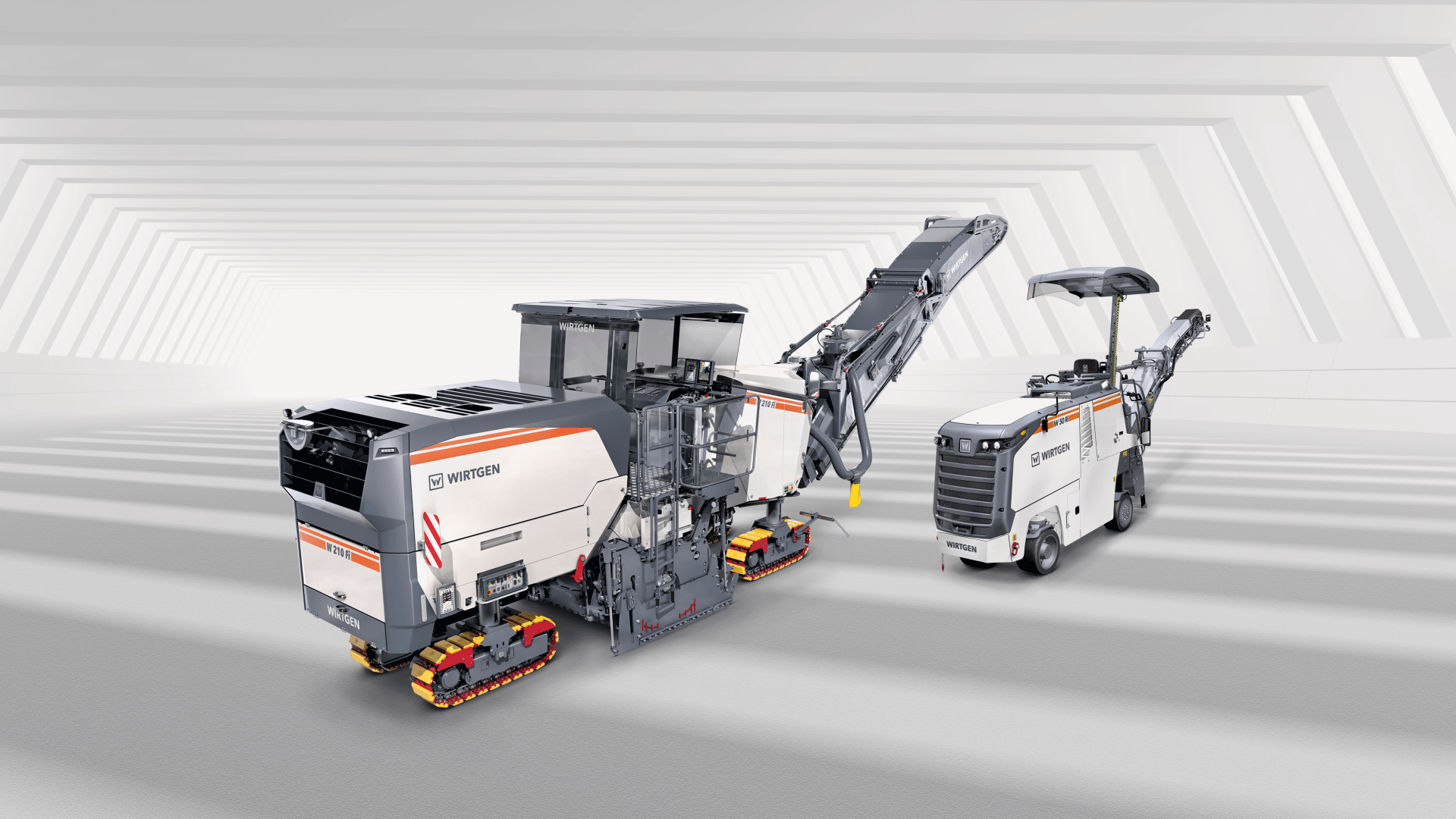

Cold milling machines

Asphalt and concrete pavements can be cost-effectively removed with cold milling machines. The range of applications extends from the complete removal of asphalt and concrete to the layer-by-layer removal and levelling of asphalt and concrete surfaces. With WIRTGEN cold milling machines, it is possible to machine working widths from 1 ft 2 in up to 14 ft 5 in and working depths up to 1 ft 2 in in a single pass. In addition, a large number of different milling drums, such as ECO cutters or fine milling drums, ensure that machines can be used with a high degree of flexibility.

Small milling machines are equipped with a wheeled chassis and a milling drum positioned at the rear. The granulated RAP which is broken up by the rotating milling drum is transferred to a slewing and height-adjustable discharge conveyor and immediately loaded onto waiting transport vehicles. The compact rear loaders are highly maneuverable and their rear right wheel can be swiveled in when milling flush to the edges of obstacles. A variety of different milling drums are available, enabling the small milling machines to cover a wide range of applications extending from partial pavement rehabilitations and tie-in milling to the rehabilitation of industrial floors.

The highly flexible compact milling machines combine the advantages of the small and large milling machine classes. The maneuverable front-loaders are easy to transport and are ideal for use on confined job sites. These powerful machines can mill off entire asphalt pavements cost-effectively. A wide range of different milling drums is available, greatly extending the possible range of applications so that the milling of individual layers and fine milling operations are also among the everyday tasks of these machines.

Large milling machines have a milling drum positioned centrally beneath the machine and a two-part front-loading system. Trucks can be loaded quickly and flexibly via the slewing and height-adjustable discharge conveyor. A variety of different milling drums and milling drum assemblies are available to cater to the wide array of milling tasks. They can be exchanged quickly and easily to suit the application. The range of applications extends from wide-scale complete removal down to a depth of 35 cm in a single pass to the rehabilitation of concrete pavements and airport runways as well as fine milling to improve pavement skid resistance.

All details, illustrations and texts are non-binding and may include special equipment. We reserve the right to make technical changes without prior notice. Performance data are dependent upon actual operational conditions.